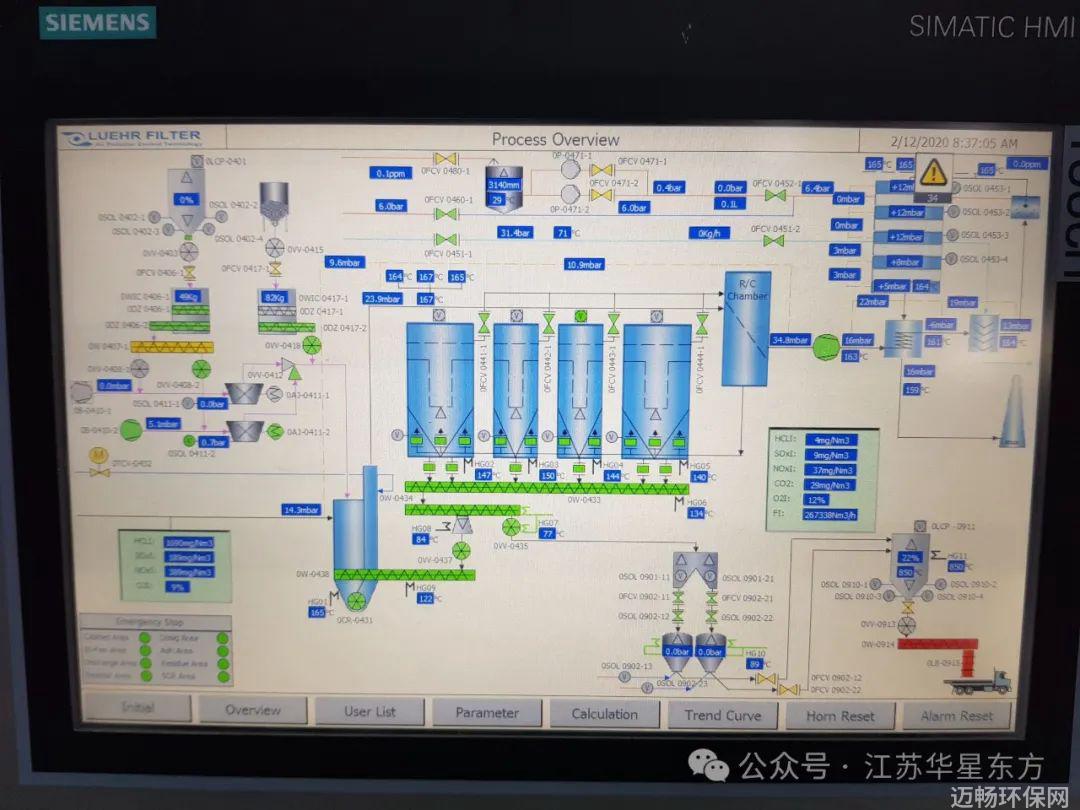

我公司承建的泰国SCG水泥集团8MW工业垃圾焚烧发电项目烟气净化工程于2019年12月22日通过调试验收。

The flue gas cleaning project of the 8MW industrial waste incineration power generation project of Thailand SCG Cement Group undertaken by our company passed commissioning and acceptance on December 22, 2019.

该工业垃圾焚烧发电项目是以工业废弃物、垃圾等为主要燃料,装机8MW。位于泰国政府“东部经济走廊”发展规划的罗勇工业区内,毗邻Lam Chabang港口。烟气处理采用“高效干法(非本次合同范围内)+布袋除尘(非本次合同范围内)+飞灰输送及存储(非本次合同范围内)+GGH+SGH+SCR+氨水存储供应系统”的烟气净化工艺,为我司设备供货工程。

This industrial waste incineration power generation project uses industrial waste, garbage, etc. as the main fuel, with an installed capacity of 8MW. It is located in the Rayong Industrial Zone under the Eastern Economic Corridor development plan of the Thai government, adjacent to Lam Chabang Port. Flue gas treatment adopts high-efficiency dry method (not within the scope of this contract) + bag dust removal (not within the scope of this contract) + fly ash transportation and storage (not within the scope of this contract) + GGH + SGH + SCR + ammonia storage and supply System flue gas cleaning process, supply engineering for our companys equipment.

泰国“东部经济走廊”作为当地产业升级的区域平台,为正在响应“一带一路”倡议的中国企业提供了更多良好的合作机遇。华星东方作为中国环保垃圾焚烧烟气治理领域的龙头企业,积极与沿线国家和地区广泛开展产能合作,大力拓展海外市场,多个项目在印尼、日本、泰国、马来西亚、印度、土耳其、挪威、西班牙等国落地实施,依靠强大的产品优势和技术优势,积极布局海外版图,努力打造成为节能环保的“一带一路”先锋。

As a regional platform for local industrial upgrading, the Eastern Economic Corridor provides more good cooperation opportunities for Chinese companies that are responding to the Belt and Road initiative. As Chinas leading enterprise in the field of environmentally friendly waste incineration flue gas cleaning technology, Huaxing East Co. has actively carried out extensive production capacity cooperation with countries and regions along the Belt and Road, and vigorously expanded overseas markets. Multiple projects have been implemented in Indonesia, Japan, Thailand, Malaysia, India, Turkey and other countries , relying on its strong product advantages and technological advantages, actively deploying expertise and resources on the overseas territory, and striving to become a Belt and Road pioneer in energy conservation and environmental protection.

华星东方在海外的业绩涵盖包括:印度南部特伦甘纳邦邓迪格市(旋转喷雾烟气净化项目)、印度海德拉巴一期、二期(SNCR+旋转喷雾烟气净化项目)、土耳其维拉卡纸厂(循环流化床烟气净化项目)、泰国SCG集团(SCR烟气净化项目)、GEA Bishoff PTFI MANYAR 金属冶炼印尼项目(SDA制造工程)、GEA Bishoff 挪威Boliden, Odda Zinc Smelt项目(高温静电+旋风除尘项目)、GEA Bishoff 西班牙AC Huelva CirCular Copper Smelt项目(高温静电+旋风除尘项目)、印尼IKS锅炉岛(烟气核心设备供货及系统工艺包设计)、印尼TK锅炉岛(烟气核心设备供货及系统工艺包设计)、马来西亚雪兰莪一期、二期(SNCR+旋转喷雾烟气净化项目)、日本长崎西催化剂供货等多个项目。

Huaxing East Co’s overseas performance covers: Dundigal City, Telangana State, southern India (rotating spray flue gas cleaning project), Hyderabad, India Phase I and II (SNCR + rotating spray flue gas cleaning project), Vila, Turkey Cardboard factory (circulating fluidized bed flue gas cleaning project), Thailand SCG Group (SCR flue gas cleaning project), GEA Bishoff PTFI MANYAR metal smelting Indonesia project (SDA manufacturing project), GEA Bishoff Norway Boliden, Odda Zinc Smelt project (high temperature Electrostatic + cyclone dust removal project), GEA Bishoff Spanish AC Huelva CirCular Copper Smelt project (high temperature electrostatic + cyclone dust removal project), Indonesia IKS boiler island (flue gas core equipment supply and system process package design), Indonesia TK boiler island (flue gas Core equipment supply and system process package design), Selangor Phase I and Phase II in Malaysia (SNCR + rotary spray flue gas cleaning project), Nishi Nagasaki catalyst supply in Japan, and many other projects.